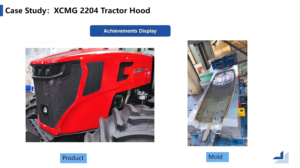

PDCPD Mold & Part Development for Large, Complex Enclosures

Engineering-driven PDCPD solutions from mold design to stable production

PDCPD Mold Applications

From design to production

Engineering Problems We Solve in PDCPD Mold Development

We can resolve issues such as surface pinholes, sink marks, material shortages at product edges/corners and boss pillars, as well as product deformation for PDCPD (Polydicyclopentadiene) products via RIM (Reaction Injection Molding).

Our PDCPD mold development capability

From design to production / Full-chain Solutions for PDCPD Exterior Components

Design Phase Deliverables

During the design phase, the following engineering documents and deliverables are provided:

Manufacturing Conditions Survey Form

(Production feasibility and process condition assessment)

PDCPD Mold DFM Analysis Report

(Design for Manufacturability analysis)

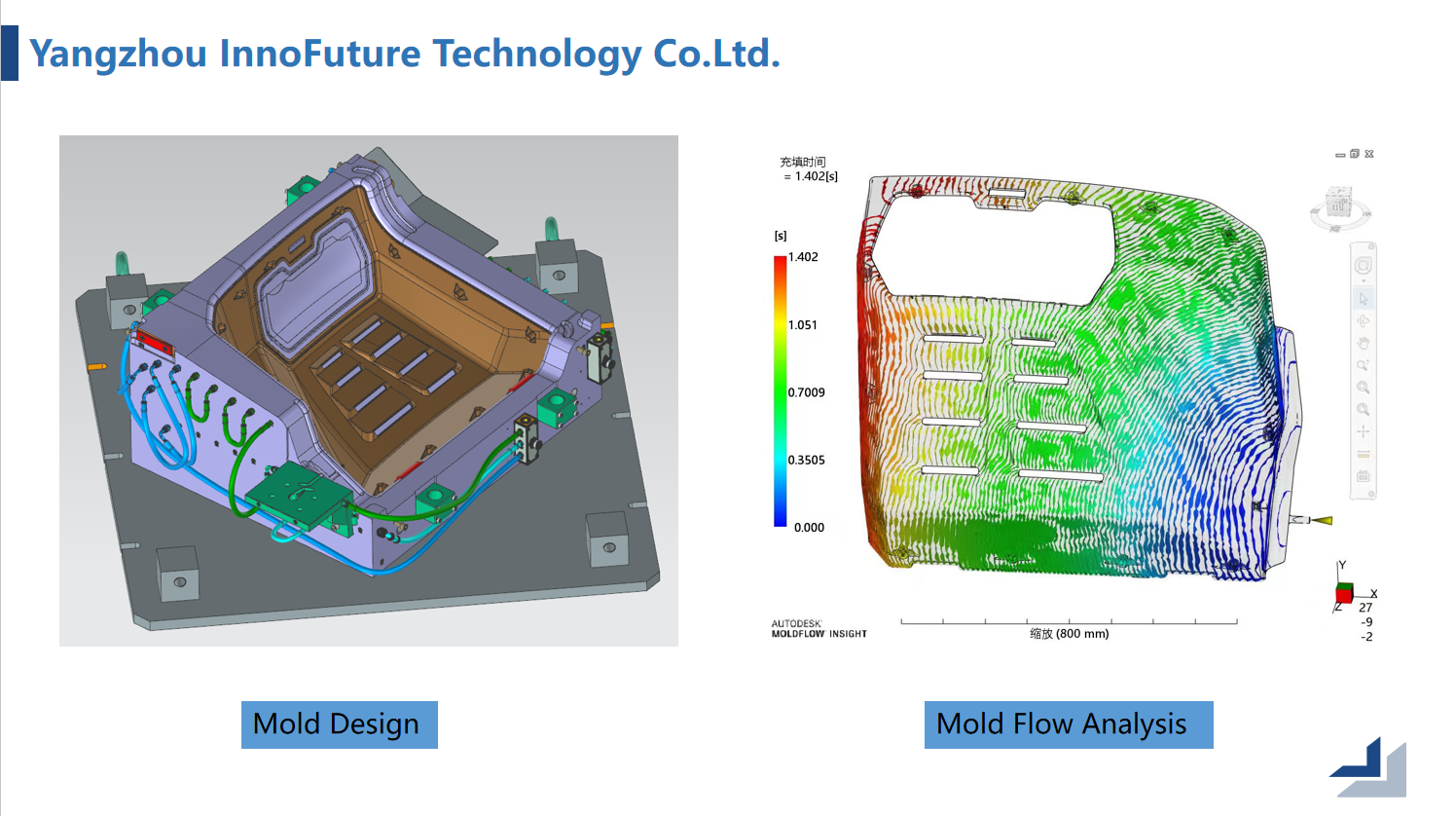

CAE Simulation Report

(Flow behavior, filling, and potential defect analysis)

Complete PDCPD Mold 3D Model

(Full 3D mold assembly including core, cavity, and main structures)

PDCPD Mold Design Review Report

(Engineering review summary and design approval record)

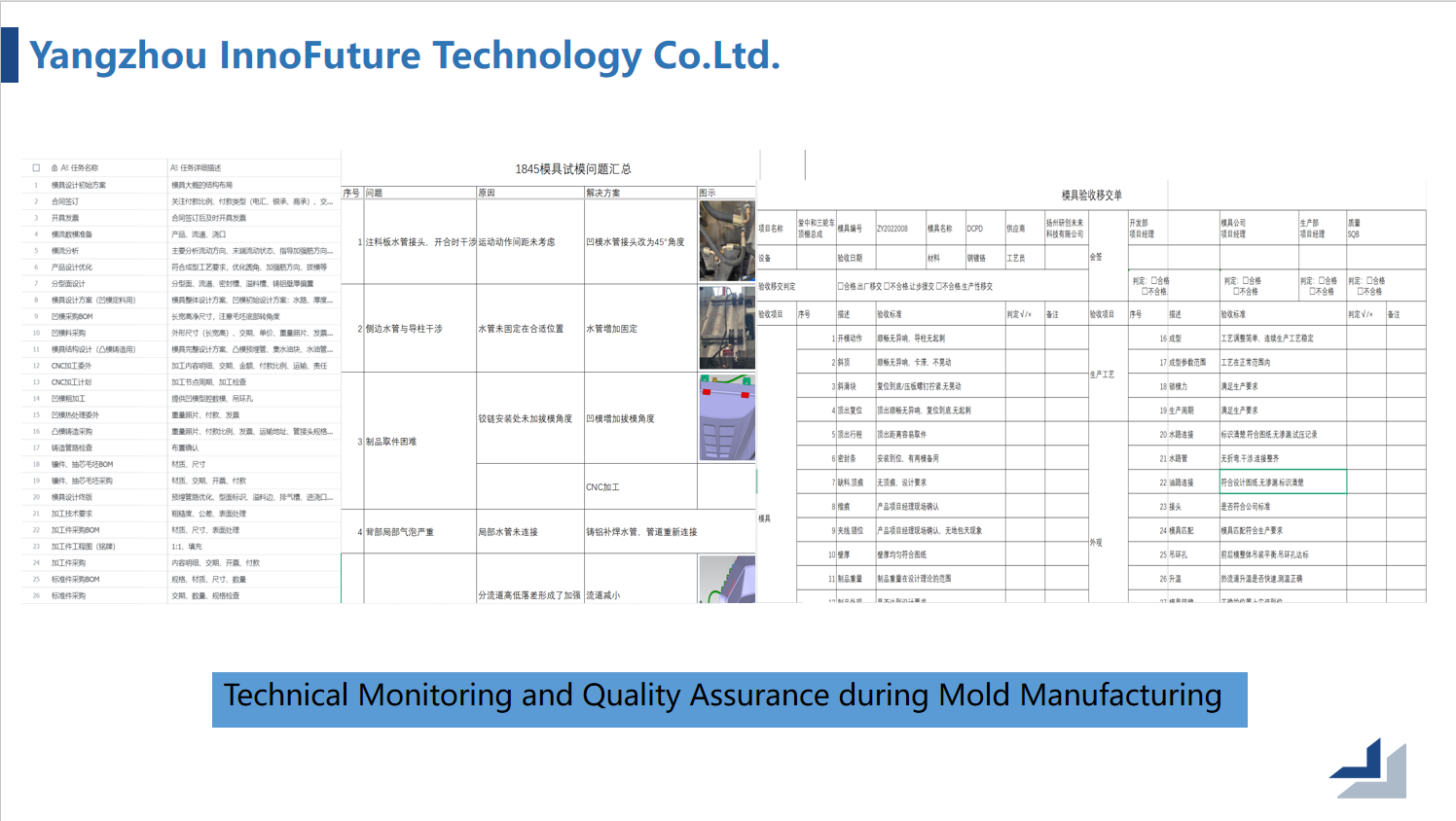

PDCPD Mold Engineering Management

Our PDCPD mold engineering management covers the full tooling development cycle, including:

Project Planning

Definition of development milestones

Engineering and manufacturing schedule planning

Schedule Tracking

Progress monitoring against project plan

Milestone-based status updates

Issue Communication & Resolution

Engineering issue identification

Technical discussion and solution alignment

Customer communication on key issues

Machining & Manufacturing Coordination

Machining process arrangement

Manufacturing sequence coordination

Quality and progress control during PDCPD mold fabrication

Manufacturing Capability Coverage

Through qualified manufacturing partners under strict engineering control, we support the following PDCPD mold manufacturing capabilities:

Large casting capacity up to 2 tons

5-axis gantry machining for parts up to 4 meters

Electroplating capability for large mold components (up to 4 meters)

Multi-axis deep hole drilling for complex mold structures

PDCPD Molding & Trial Molding

We support both trial molding and batch production under controlled conditions.

The molding and trial molding stage includes:

Complete Trial Molding Equipment & mold

(Dedicated trial molding equipment, fixtures, and auxiliary tools)

Experienced Operators

(Skilled operators familiar with PDCPD molding and mold operation)

Trial Molding Request Form (Pre-Trial)

(Formal application and preparation checklist before trial molding)

Trial Molding Report (Post-Trial)

(Trial results, process parameters, and improvement recommendations)

Trial Molding & Batch Production Capability

(Support for trial runs as well as batch PDCPD molding)

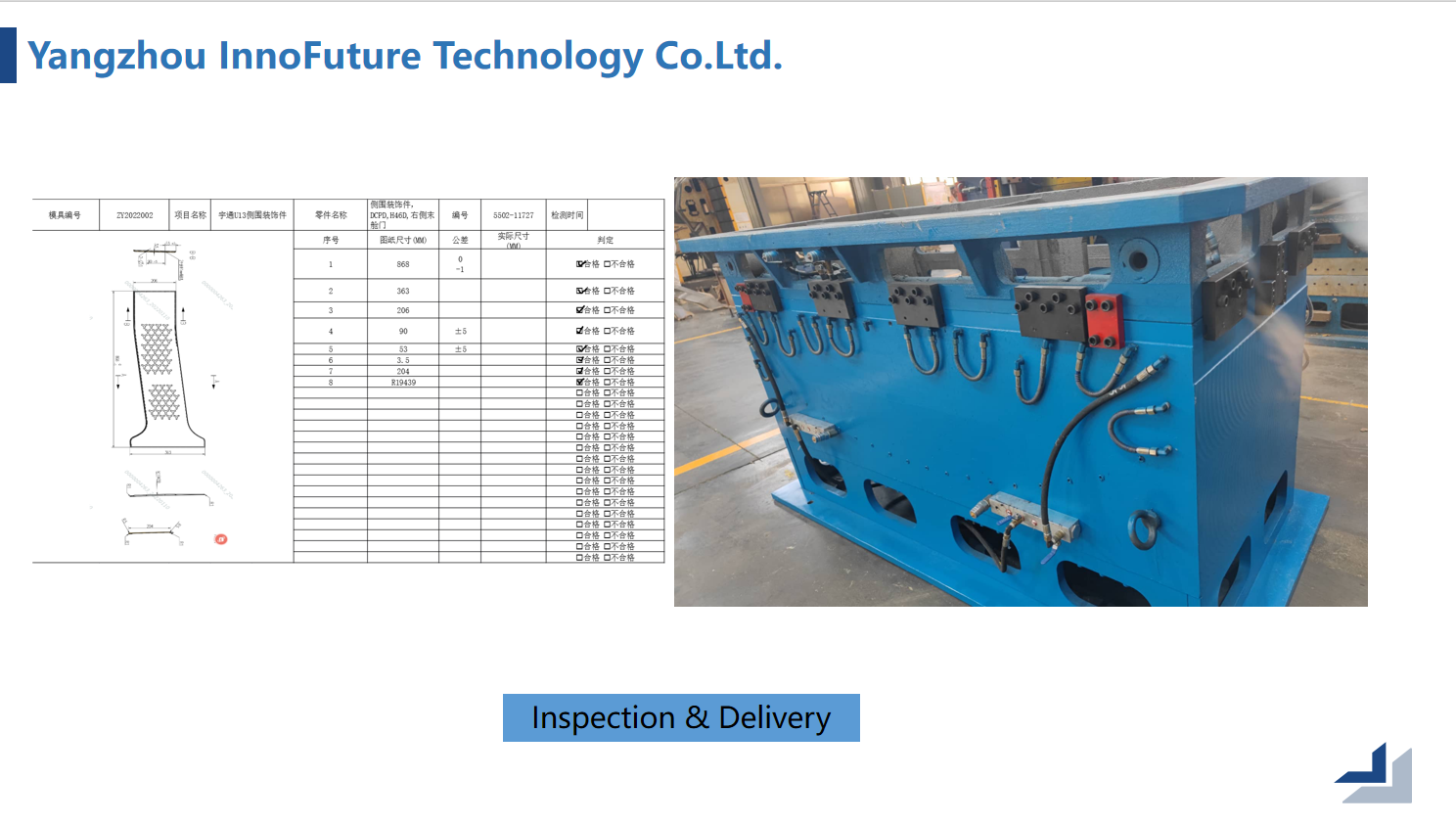

Inspection & Delivery

Before PDCPD mold delivery, a complete inspection and validation process is conducted.

The following documents and deliverables are provided:

PDCPD Mold Inspection Checklist

(Structural, dimensional, and functional inspection before trial and delivery)

Trial PDCPD Mold Report

(Trial results, process parameters, and improvement records if applicable)

Full Dimensional Inspection Report of PDCPD Parts

(Comprehensive dimensional measurement of trial parts)

PDCPD Mold Operation, Maintenance & Service Manual

(Operating instructions, maintenance guidelines, and service recommendations)

PDCPD Mold Handover Document

(Formal mold transfer and acceptance record)

Spare & Wear Parts List

(List of consumable and wear components for long-term operation)

Why Work With Us

We help OEMs and industrial manufacturers develop reliable PDCPD parts where size, structure, and consistency matter

10 Years of Focus on PDCPD Mold Development

understanding of PDCPD RIM process constraints

OEM-oriented documentation & communication

without skipping any step or cutting any corners

Have a PDCPD project?

FAQ

Is my PDCPD project information protected by NDA?

All drawings, specifications, and project-related information shared with PDCPDmold are treated as confidential and protected under NDA.

Typical PDCPD mold lead time?

Usually 6–10 weeks depending on complexity.

What is the size and weight limitation for PDCPD parts?

Currently, our PDCPD part capability includes:

- Maximum part dimension: ≤ 4 meters

- Maximum part weight: ≤ 40 kg

What are your payment terms?

Our typical payment structure is as follows:

- 10% down payment – Engineering design files are prepared and reviewed

- 30% payment – Ordering of forgings and castings

- 30% payment – Machining and tooling manufacturing

- 20% payment – After trial mold approval (T1 / trial OK)

- Remaining balance – Paid before shipment

Do you provide trial PDCPD mold service?

Yes.

Trial molding service is available and includes:

- PDCPD Mold trial and functional verification

- Initial part evaluation

- Engineering feedback for PDCPD mold optimization if required

Do you manufacture PDCPD molds in-house?

We perform in-house PDCPD mold engineering and project management, while tooling manufacturing is carried out by qualified partners under our strict control.